Redefining Sustainability in Jewellery Packaging: Thai Design’s Compostable Innovation

At Thai Design, jewellery is at the heart of what we do — but so is caring for our planet. We’ve been exploring new ways to reduce our environmental impact across every part of our business. And this year, we’re proud to share an exciting milestone in our sustainability journey: the introduction of truly compostable jewellery packaging.

Each week, our team ships thousands of jewellery pieces worldwide. This makes packaging one of the most visible aspects of our operation — and a critical opportunity to make a difference. While we’ve always strived for sustainable jewellery production in Thailand, we realised that even small details like packaging could have a wider impact on the planet.

The Shift from “Biodegradable” to Truly Compostable

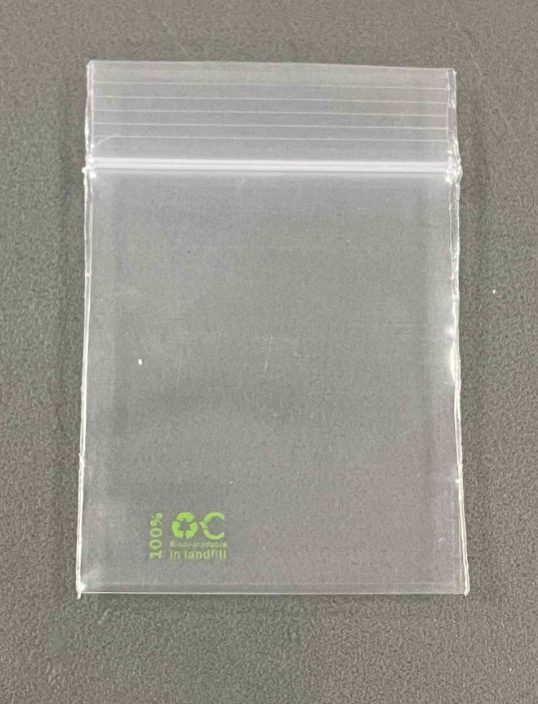

For the past few years, we’ve been using biodegradable plastic bags — a step up from traditional plastics, but not a perfect solution. Many “biodegradable” plastics only break down in industrial facilities, meaning they can still linger in landfills for years.

To address this, we began researching alternative packing materials and suppliers, focusing on truly compostable materials that align with our values of ethical jewellery production.

Within Thailand, a hub for bioplastic innovation, we found Sugarbased, a local pioneer transforming renewable agricultural waste (like sugarcane bagasse) into home-compostable packaging. These materials naturally decompose within about 45 days, returning nutrients to the soil — a perfect example of sustainable production done right.

Partnering with Sugarbased not only supports local innovation but also helps us reduce carbon footprint impacts in jewellery production by cutting down on fossil-fuel-based plastics

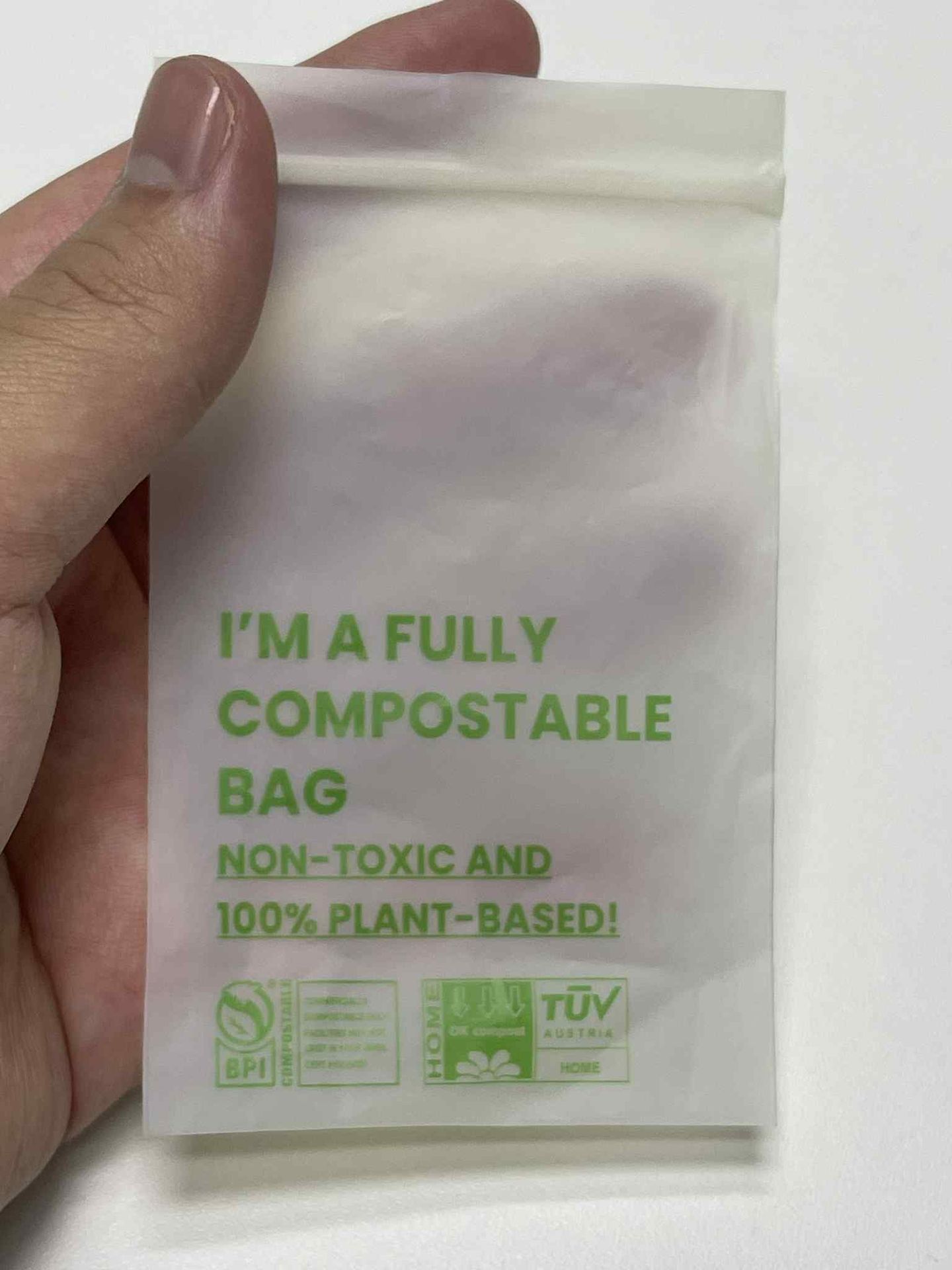

The Old One The New One

It wasn’t as simple as switching materials. Because we manufacture everything from delicate stud earrings to large heavy bangles and silverware, existing packaging sizes didn’t fit our needs. We collaborated closely with Sugarbased to create new formats from scratch, investing in tooling and development to ensure our packaging performs as beautifully as it looks.

The result? A bespoke range of home-compostable zip-lock bags designed exclusively for our jewellery. Each bag is fully compostable, printed with eco-conscious messaging, and made to perfectly protect each piece. We even customised the graphics to reflect our sustainable values and craftsmanship!

In addition to our new compostable bags, we continue using our much-loved honeycomb paper for cushioning and wrapping, and we’ve introduced biodegradable outer bags for bulkier shipments. We’re also testing glassine paper — a recyclable, fully compostable option we plan to roll out soon.

Quality, Functionality, and Real Customer Feedback

All our new packaging has passed internal quality trials and is now in active use for shipments worldwide. The feedback has been amazing — one client recently shared how much they loved the new outer bag and are even planning to switch to similar materials for their own customers!

This kind of response reinforces why we do what we do. By setting higher standards and being transparent about our sustainability journey, we hope to inspire our customers and peers to join in addressing sustainability challenges in jewellery production globally.

Rethinking Every Detail

We believe that ethical jewellery production in Thailand goes beyond the product itself. Every small choice matters —We believe that ethical jewellery production in Thailand goes beyond the product itself. Every small choice matters — from the materials we use to even the tape that seals our boxes. While we’ve already switched from plastic to paper tape, we’re now testing an innovative cellulose biodegradable version made in Thailand. It’s strong, renewable, and yet another creative way to reduce our reliance on fossil fuels. made in Thailand. It’s strong, renewable, and yet another creative way to reduce our reliance on fossil fuels.

This isn’t just about changing materials — it’s about a mindset. We’re continuously questioning, testing, and improving how we work. Sustainability challenges in jewellery production aren’t solved overnight, but we’re proud to take consistent, meaningful steps forward.

Creating Positive Change Together

We understand that not every customer is as deeply involved in packaging choices as we are. Some are simply used to receiving jewellery in standard plastic bags or bubble wrap. But by leading through example and sharing our progress, we hope to raise awareness across our supply chain.

Every reuse, every small sustainable switch, and every informed decision counts. Whether it’s reusing our compostable bags for jewellery storage (which also helps keep pieces tarnish-free) or finding creative ways to repurpose natural materials — like using dried hyacinth stems for wrapping and decoration — these small habits contribute to reducing the overall carbon footprint in jewellery production.

Final Thoughts

Our sustainability journey is ongoing, and while we’re not perfect, we’re proud of the progress we’ve made. From sustainable jewellery production in Thailand to sourcing responsibly and minimising waste, every choice we make reflects our commitment to doing better — for our customers and our planet.

Thank you for supporting us on this journey. Together, we can continue to redefine what ethical and sustainable jewellery production truly looks like.