Your Journey Starts Here

Design Development

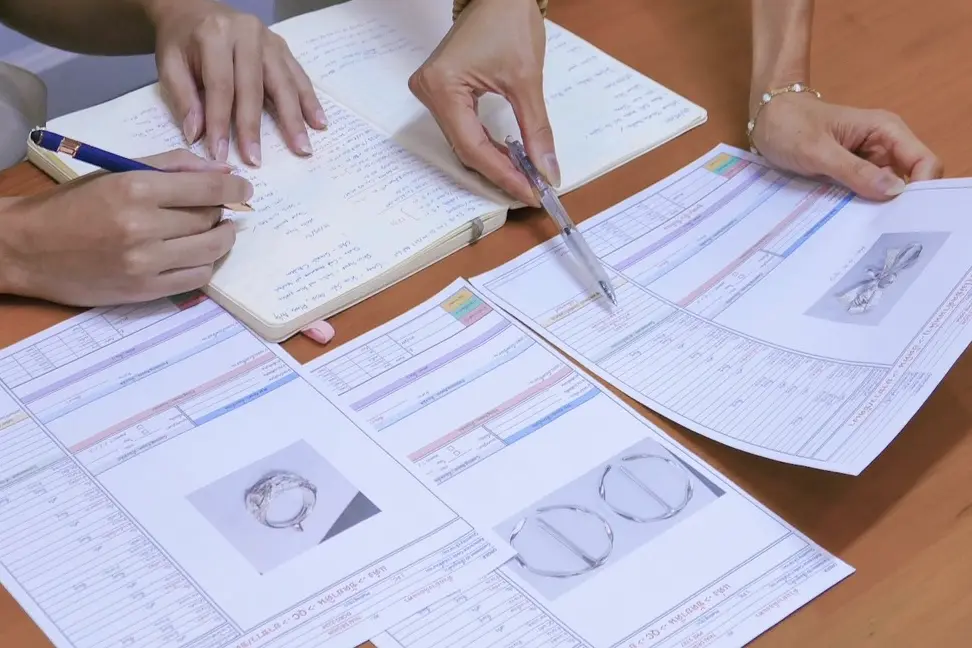

Where it all begins

We are grateful and proud to have customers that have been with us for decades, and we love when new brands reach out to us. Design development is where it all starts. Some brands start with one great design idea, while others come to us with multiple collections. The process may very vary slightly, but the goals are the same: Deliver samples that delight & excite, provide excellent support throughout the entire development process, and make it easy to move into production.

Seven Easy steps

2- Quotes

Jewellery prices are something of a moving target, but we offer the clearest and most consistent pricing guidance possible throughout the development process. Initial designs are often theoretical, so to begin with, we rely on our extensive experience for reliable estimates. Once refined, we offer the first design quotation free of charge, whilst subsequent quotations for amendments are subject to a fee of £20/$25/€25 per design.

This non-refundable fee enables us to thoroughly assess your specifications, covering material selection, labour, and potential production challenges. To

support your development process, this fee can be credited toward your development deposit.

1- Design Support & Guidance

Our dedicated support staff are highly regarded for exceptional service, whether you’re a jewellery veteran or spreading your wings for the first time. Working across both the UK and Thailand, we’re here to guarantee a smooth journey. As a client of Thai Design, we promise you a passion for beautiful things and full support, transparency and efficiency from design concept to finished jewellery product. Our exceptional service is attested by the loyal clients who have been returning to us for decades.

Whilst many other suppliers distance themselves from brands that are ‘too small,’ we’re committed to minimising barriers. Our minimum order quantity starts at 10 pieces; low enough to support artists and new businesses as they grow.

3- Custom

Jewellery Sample

Jewellery samples provide a frame of reference on weight, texture, size and construction, making reliable quotes a little easier to generate in the first instance.

It’s great when a client gives us a head-start with a physical sample to begin working from. This being said, it’s not a problem if you don’t have one already prepared. In fact, the aim of the design development stage is to produce a perfect sample collaboratively; we’re here to support you through that process.

Thai Design takes intellectual property rights seriously. Please note that we cannot replicate a sample unless we’re confident that its design belongs to you. Likewise, any design that you develop in-house with us here is your exclusive property.

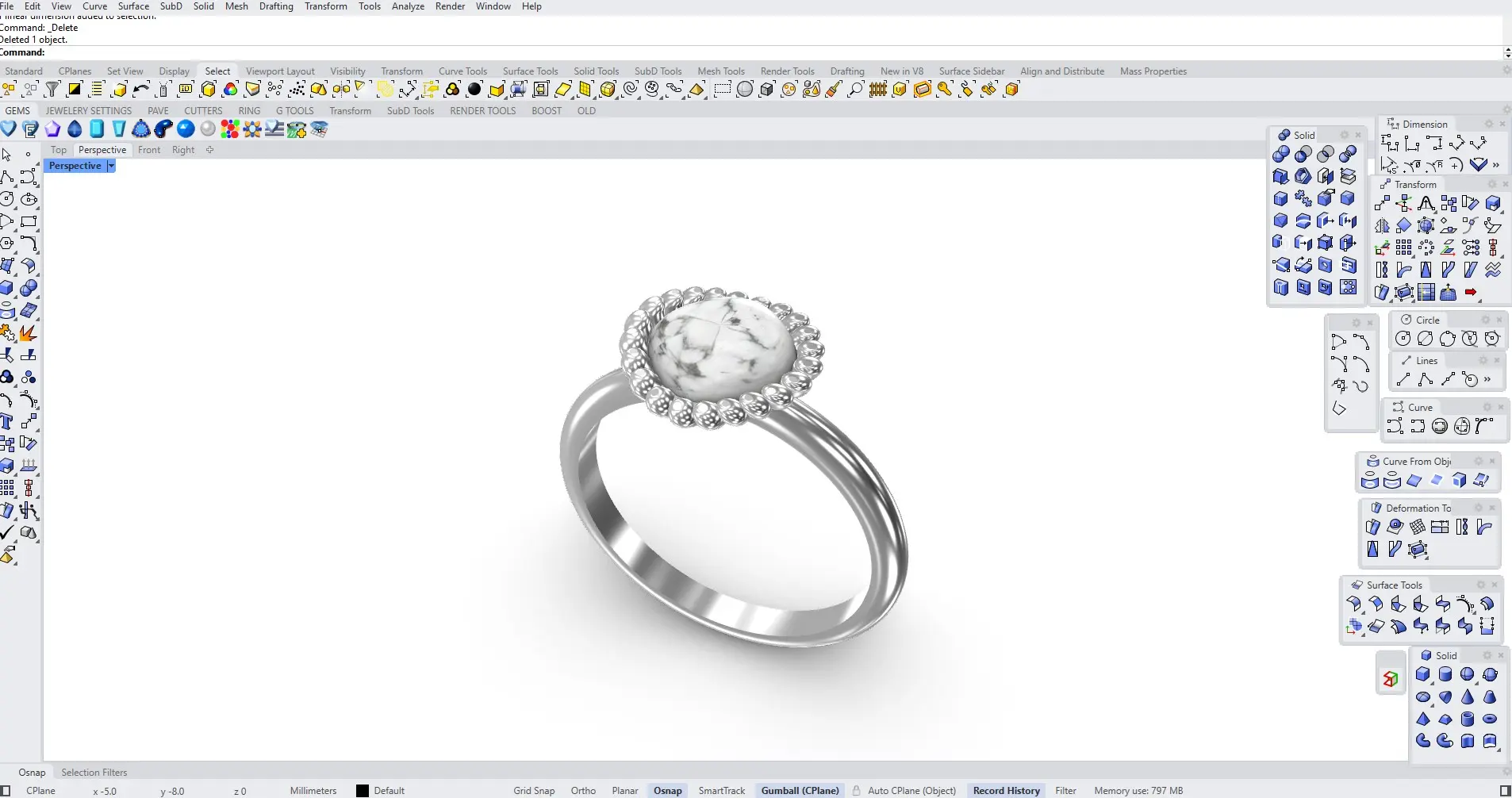

4- CAD

Computer Aided Design (CAD) is a highly versatile tool, particularly for 3D designs. CAD images can be viewed, rotated and rendered in many ways, allowing for a deep and tactile understanding of a jewel’s presence and detail. CAD is not only useful in the design process; it can also assist in accurate and consistent production.

Once a sketch is finalised, our second in-house CAD designer is dedicated to converting those sketches into CAD files that can be shared and amended with ease. We charge for this specialised service, though you’re more than welcome to provide your own CAD files if you’d prefer the ability to seek and communicate with a CAD artist independently. With the best interests of yourself and your design at heart, we’re flexible in how we collaborate with you as a partner.

5- 3D Resin or Wax

Traditionally, a talented artisan was required to carve 3D representations of jewellery designs in wax with incredible skill and detail. Whilst we’re proud to preserve this craft internally, we also enlist the efficiency and accuracy of our facility’s high-tech 3D printer a lot of the time.

CAD files are transferred to the printer, which creates a physical prototype by precisely building layer upon layer. Once supports are cut and details refined, the full process is completed in only a matter of hours.

A 3D wax model is not only a useful opportunity to see and handle a design before final production; it helps to provide accurate weight estimates for pricing quotations, and it’s critical for making moulds used in the casting process.

Whilst you’re more than welcome to provide your own 3D resins or waxes for us to work from, it’s worth considering the fragility of these models when shipping them to us. Thai Design’s 3D printing service is priced competitively, and producing models in-house guarantees greater consistency in the process, offering a smoother experience and a more reliable end-product.

6- Masters, Moulds and Dies

Producing and reproducing a jewellery design accurately requires knowledge and understanding of the tools available. Our experienced crafting facility will draw on their experience to determine which process is most suitable for bringing the unique characteristics of your designs to life: casting, stamping, or both.

Casting utilises special moulds that can be replicated from a physical master and tweaked for size. Thai Design’s attention to detail ensures strict standards for masters, ensuring no defects are transferred to the mould. Thai Design charges for any masters or moulds created in-house, but our team is always transparent about manufacturing plans to avoid surprises and provide you an educational insight into the production process.

Meanwhile, stamping relies on a metal precision tool called a ‘die,’ designed to imprint your jewel with detail by way of pressure. Although the price to create a custom stamping die might seem expensive, it’s an upfront cost that can be offset by lower jewellery metal weights and/or less labour as we progress into the next stages of production, and future repeat orders.

7- Finished

Jewellery Samples

At the end of the design development process, you’ll receive a completed sample. This sample illustrates that we understand your vision and showcases the technical skills of our craft team.

Some samples are ‘auditions,’ a chance for us to deliver results that impress and honour our opportunity to collaborate with you. Other samples are experiments, enabling us to confront challenges creatively and make collaborative decisions about production with confidence.

Sample development is an opportunity for us to refine expectations and plan forwards for successful production.

Customisation

Custom jewellery, tailored to your brand

To ensure your finished product is truly reflective of your vision, we offer exceptional flexibility in design and materials. Whilst the most common customisations are detailed below, additional adaptations are possible - please don’t hesitate to share your ideas with us.

Thickness

Reducing thickness is a common way to lower the cost of a design, but there is always a balance between price and quality to consider. Undoubtably, there is something about the weight and feel of the piece that provides extra assurance and a sense of luxury.

Thickness and weight also impact comfort and a piece may need to be adapted with this in mind. Regardless of the reason, you can specify the thickness you desire. Our experienced team will help determine the optimal specifications to meet your needs.

Size

See something you like but it is just not the right size?

Simply let us know how big you want it to be and we can re-size it for you. Whether you need something bigger or smaller, it can be done. It is always easier for the factory to work to specific dimensions, so please have your measurements in mind.

Hand Engraving

Hand engraving maintains a traditional, yet timeless appeal. Items may be fully or partially engraved, giving customers a wider range of options. Scroll and floral motifs are typical of the craft, and can be borrowed from and blended with elements from a range of patterns to create something special and unique.

If you have a particular pattern in mind, please let us know. We would be happy to consult our talented team on your behalf.

Laser Engraving

A modern alternative to hand engraving, a laser can be used to achieve an exceptionally precise and consistent product. This technology is ideal for logos, text, and detailed graphics, which would be extremely difficult or impossible to reliably replicate by hand. Almost anything can be done, but our team is on-hand to explain any limitations and to provide recommendations to ensure success.

Plating

Plating is a simple way to expand the breadth of your jewellery range, but it can also be employed to impart a touch of luxury or provide additional protection. Our most popular plating options are yellow gold, rose gold, white rhodium, and black rhodium - but additional options are available.

Beyond colour, the thickness of the plating - its ‘micron’ volume - is a critical consideration. Most of our plating is 1.0 microns thick, but many customers prefer 2.5 microns for gold plating - or ‘vermeil’ - a weighty casing that’s considerably more durable than plating. Thicknesses between 3.0 microns and 5.0 microns are possible, but are much less commonly requested.

Physical Vapor Deposition (PVD) is a relatively recent alternative to traditional plating, providing a relatively high hardness and chemical resistance (sweat, lotion, etc.) at a low price-point.

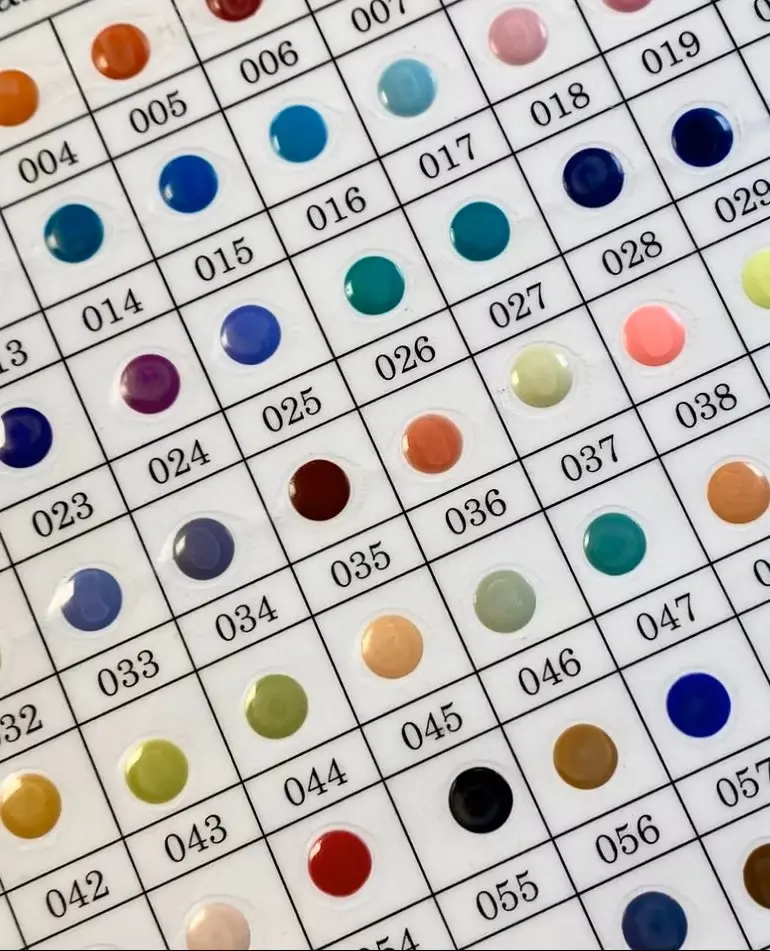

Enamel

The team at our crafting facility is skilled in the application of cold enamel (also referred to as lacquer enamel), which provides designers with a wide range of vibrant colours to choose from. Pigmented resin is applied onto metal, dried, and then polished to a high shine.

While the application of coloured enamel is certainly a capability, the team really excels with the use of clear resin. Working in small batches under optimal conditions, and with quality materials, the team can achieve beautiful results that are exceptionally resistant to yellowing over time.

Although we are rarely asked for hot enamel (also referred to as vitreous enamel), we have an excellent local partner that is able to assist if ever needed.

Stones

Thailand is a world leader in gemstone setting because of its active market, affordable prices and a history of gemstone cutting that dates back to the 1400s. The local craftspeople working in our production facility are equipped to source and set a rich variety of gemstones, promising excellent value for money.

From ruby to sapphire, topaz to lab-grown diamonds; Here we have access to a wealth of responsibly sourced treasures with simple, transparent supply chains. We’d be here all week if we were to list every possible opportunity; please just enquire about your chosen gem and leave the rest to our sourcing team and their strong, reliable network of suppliers.

Shell

Long-term relationships with the specialist shell vendors local to us in Thailand ensure excellent quality, consistency and prices. Once sourced, our experienced inlay team start by identifying the best parts of each unique shell. Expertly, they balance this quality optimisation with waste reduction, with the best interests of both customer and Mother Nature at heart.

After the initial rough-cut, each piece of shell is carefully trimmed and filed to fit the jewellery design in question. Variations in colour are an inevitable (but charming!) aspect of working with a natural material like shell; our experienced team is highly skilled in sorting and selecting pieces that complement one another for ultimate consistency .

Finish

The ‘finish’ is the final impression of a piece of jewellery, achieved primarily through polishing, texturing or chemical applications. Here at Thai Design, a variety of finishes are available - from high-polish to matte and hammered - attained via both hand and machine.

The characteristics of any design must be considered when choosing a finish and the process by which it is achieved. Our team of experienced craftspeople draw upon a long legacy of hand craft and an extensive understanding of modern technology to ensure optimal results.

Ready to Discuss

Your Designs and Ideas ?

Click the button below to fill the form to reach out to us.

Someone from our sale department will get back to you as soon as possible

New Client Questionnaire

Tell us about yourself and your brand!

Someone from of our sales support will get back to you asap!

Someone from of our sales support will get back to you asap!