Production

Our Production

Committed to showcasing the genius of Thai artisanship for 50 years, it’s our privilege to continue this mission today by illuminating the processes that bring your bespoke jewellery to life. Each design is unique, requiring expert touch and a production journey tailored to its specifications. Here’s an idea of what yours might entail…

Casting

First, a rubber mould is formed around a metal master, or a silicone mould around a resin print. The result of the collaborative design development stage, your expertly crafted mould is owned by you and stored safely to ensure exclusivity. When you place an order, your corresponding mould is filled with high-performance wax, set aside, then delicately opened to remove a perfect wax copy.

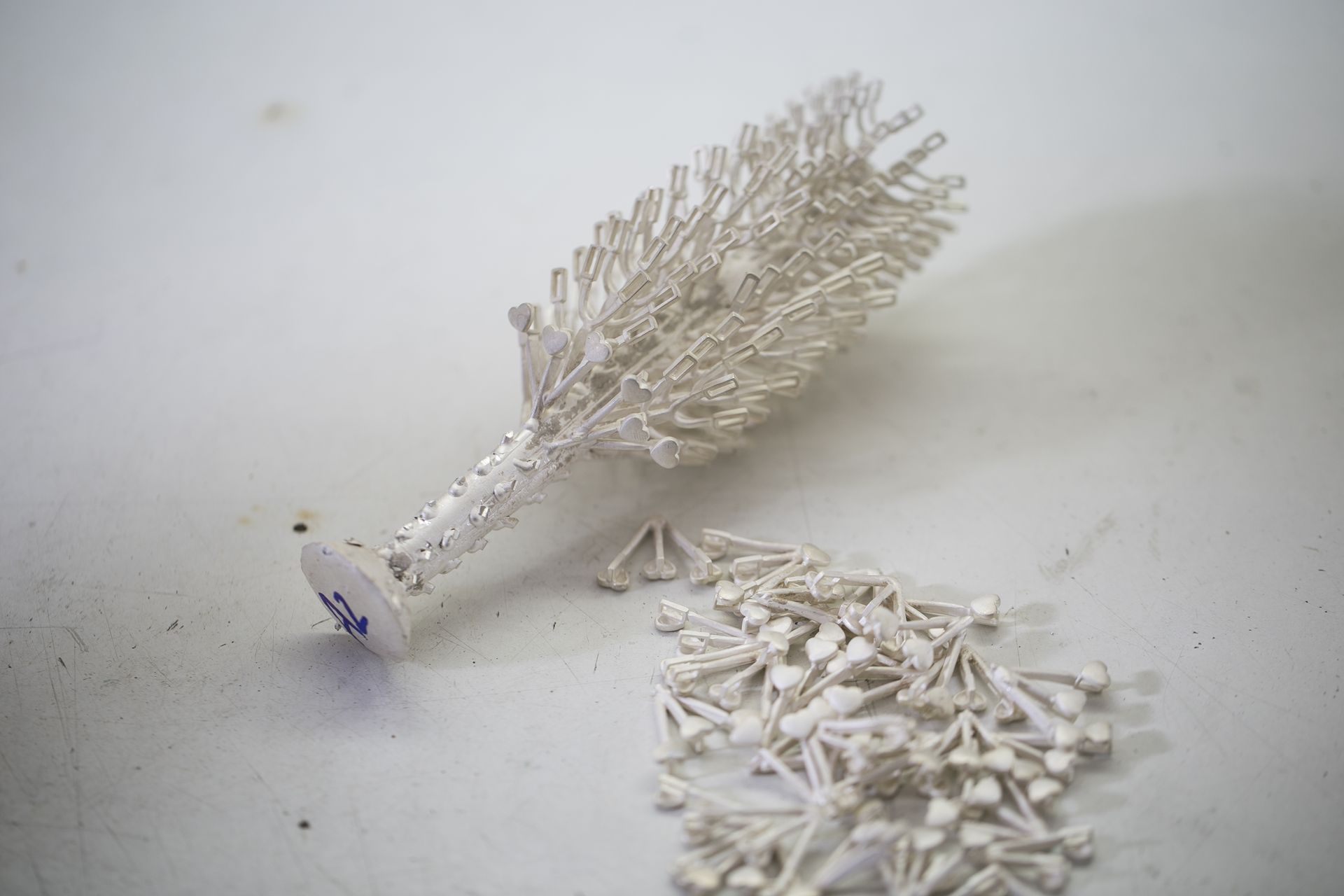

A ‘tree’ of the same design or similarly-shaped pieces is very carefully built, ensuring consistency. A resilient ceramic material we call ‘investment material’ is then poured into a flask positioned around the tree. Once hardened, the plaster-like material is heated in a large furnace, allowing the wax to be burned out and ‘lost’. The flask is transferred to a casting machine, melted metal is dropped into it, neatly filling the voids of the ‘lost wax.’ Each metal casting is cleaned and carefully inspected before being passed on to the next department.

Stamping

If our specialist team decide that lost wax casting is not the most suitable process for your unique design, the production process may instead begin with molten metal that’s poured into a form, creating a block - or ‘ingot’. The ingot is then rolled down into sheets of the required thickness for stamping, or is passed through a series of profiles and dies to create wire.

A thunderous mechanic press creates the initial form, before hand-cranked machines are used for cutting into individual components. Both machines require heavy-duty steel dies that are custom-made for each design, but can be used over and over for years. Once stamped, each component is carefully inspected before being handed over for assembly. The stamping room is like a machine shop, with an array of fabrication equipment that can also be used to create tools for other departments.

Assembly

Filing is generally the first step in the assembly process. Pieces that have been cast will bear at least one sprue - the channel that allows molten metal to be poured into the mould to create the cast - that must be filed away. Often, newly-cast pieces also emerge with a rough skin that needs smoothing.

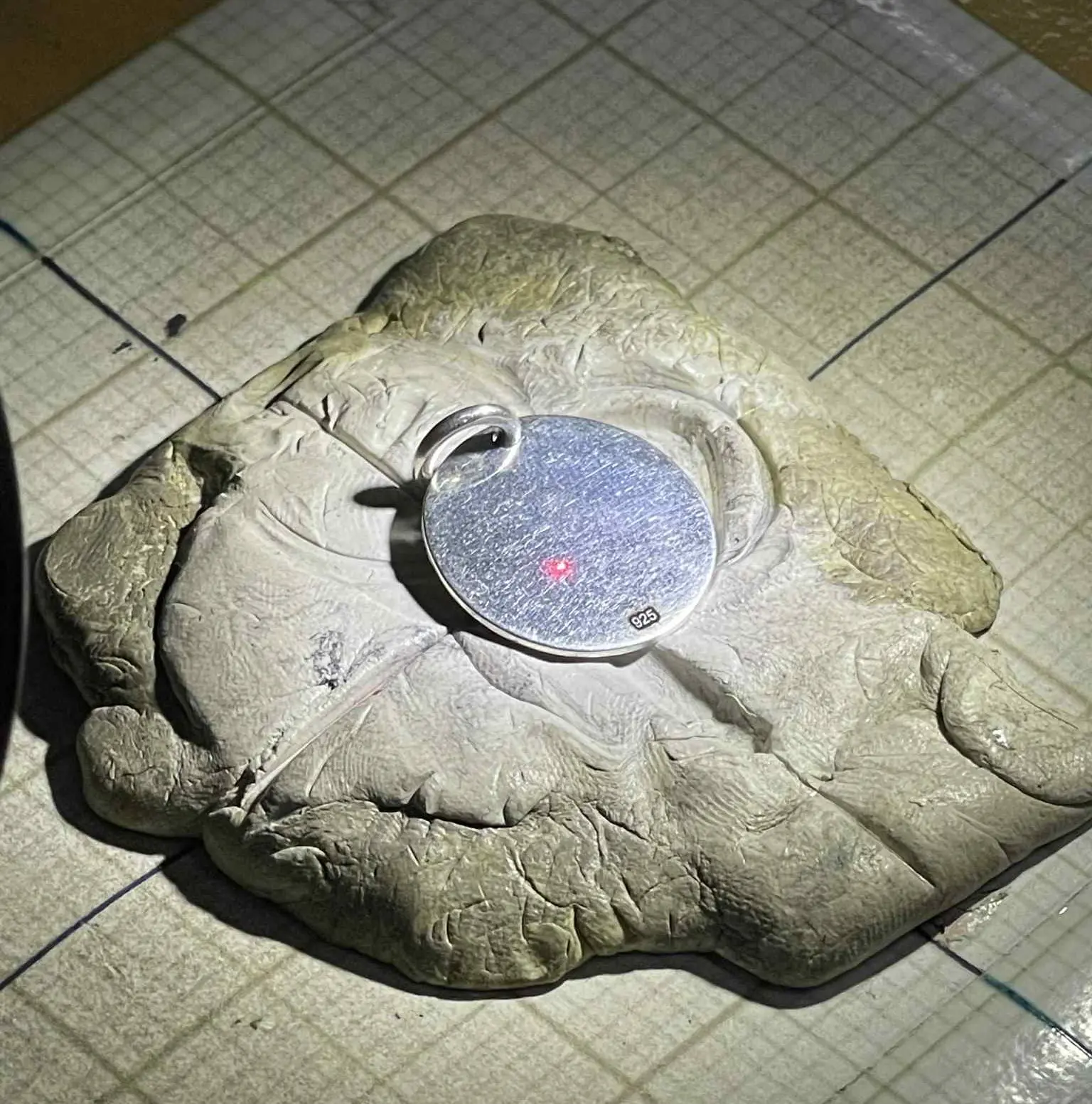

Simple designs may only have a single component, but more complicated designs may consist of many. Soldering is the process of joining two metal surfaces to one another. Traditional jewellery torches are frequently used to heat the metal until it’s reached soldering temperature, but our crafting facility also employs modern options like a laser welder and a pulse welder that provides fluctuating currents to provide quick, seamless soldering.

Polishing

The desired finish is achieved by a highly-skilled team using a combination of mechanical and hand polishing processes. The crafting facility has a state-of-the-art OTEC disc finishing unit from Germany, as well as traditional tumble and magnetic polishing tools, all of which provide a versatile range of automated finishing. Often, a design will have some degree of mechanical finishing, followed by hand-polishing. Depending on the finish desired, hand-polishing can be a three-step process. Akin to sandpaper, an increasingly fine grit is applied, making the design smoother and more shiny.

Stone Setting

At Thai Design, a small team of talented stone-setters is responsible for securing gemstones of all shapes and sizes. Bezel, claw and pavé are just a few common examples of the setting styles possible here. The art of stone-setting requires not only incredible precision but a degree of creativity and flexibility from each setter to ensure optimal fit and display.

Hand Engraving and Lasering

Meanwhile, hand-engraving is an art form that dates back roughly 500,000 years. Sharpened steel tools called gravers, chisels, scrapers and scorpers are carefully pushed by hand, slicing the metal’s surface. It’s truly wondrous to watch a hand-engraved motif come to life, but there’s a practicality to this in-house capability, too; our hand-engravers are skilled in the clean-up of sprues on cast pieces with complex surfaces.

Ready to Discuss

Your Designs and Ideas ?

Click the button below to fill the form to reach out to us.

Someone from our sale department will get back to you as soon as possible

New Client Questionnaire

Tell us about yourself and your brand!

Someone from of our sales support will get back to you asap!

Someone from of our sales support will get back to you asap!